Laser processing is a rapidly developing special processing technology that has the characteristics of high precision, high speed, and high adaptability. At the same time, it also has the advantages of narrow cutting seams, good processing flexibility, and small heat affected areas. It has become one of the key technologies for developing China's emerging industries and improving traditional manufacturing.

How can we maximize the effectiveness of laser cutting equipment and greatly improve work efficiency? Let's take a look at the maintenance work of laser cutting equipment.

1、 Use a vacuum cleaner once a week to remove dust and dirt from the machine, and all electrical cabinets should be tightly closed to prevent dust.

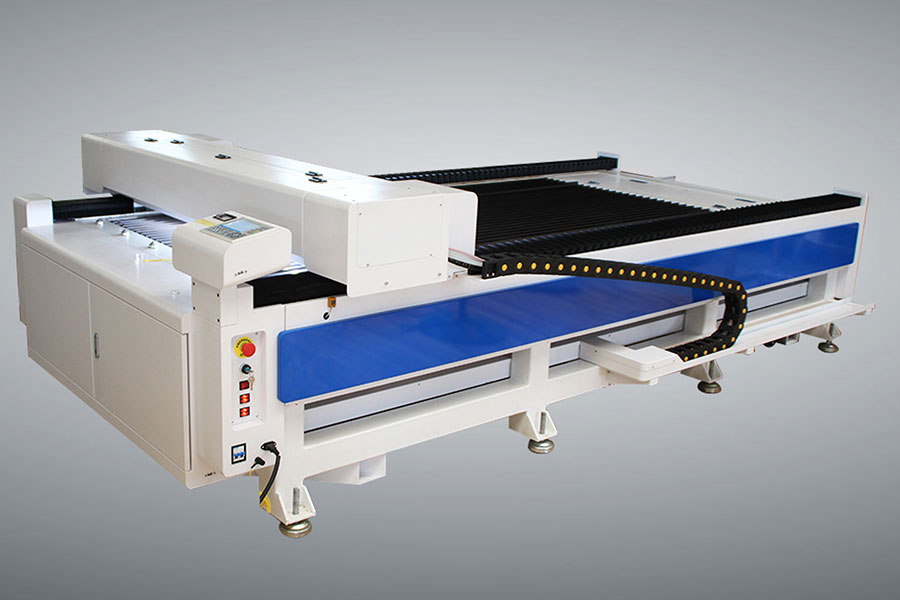

Laser cutting machine

2、 Check the straightness of the track and the verticality of the machine every six months, and promptly maintain and debug any abnormalities found. If this is not done, the cutting effect may not be very good, and the error will increase, affecting the cutting quality. This is of utmost importance and must be done.

3、 Each guide rail should be regularly cleaned to remove dust and other debris, ensuring the normal operation of the equipment. The rack should be regularly wiped and lubricated to ensure lubrication without debris. The guide rail needs to be cleaned and lubricated regularly, and even the motor needs to be cleaned and lubricated regularly. This will enable the machine to move better and cut more accurately during travel, resulting in improved product quality.

4、 The dual focal length laser cutting head is a vulnerable item on the laser cutting machine, and long-term use can cause damage to the laser cutting head.

5、 Regularly check the steel strip of the laser cutting machine to ensure it is tightened. Otherwise, if there is a problem during operation, it may cause injury to people or even death in severe cases. The steel strip may seem small, but if something goes wrong, it can still be a bit serious.

Summary: In short, regular inspections and repairs should be carried out. If there is deformation or other forms, you should know that the laser cutting head has been slightly damaged and needs to be replaced. Not replacing can affect cutting quality, increase costs, and some products may require secondary processing, reducing production efficiency. The laser cutting head should be produced by a professional manufacturer, and it should be carefully inspected when purchasing to avoid problems when used.